Last updated on February 12, 2023

Aircraft maintenance technology has advanced quickly in recent years, with an emphasis on enhancing safety, cutting costs, and boosting efficiency. The industry keeps pushing the limits of what is feasible with the use of artificial intelligence, predictive maintenance, more sophisticated materials, and novel inspection procedures. These developments have accelerated and enhanced the effectiveness of maintenance procedures while also increasing the reliability of airplanes. The utilization of innovative tools, procedures, and systems that are transforming the way maintenance is carried out will be covered in this work along with some of the most recent advancements in airplane maintenance technology. Latest innovations in aircraft maintenance technology are:

- 3D-Printed Parts

- Augmented Reality

- Enhanced Engine Mounts

- Predictive Maintenance

- Blockchain

- Robotics

The production of spare parts and components for aviation maintenance is being done more and more with the use of 3D printing technology, sometimes referred to as additive manufacturing. Some benefits of 3D printing in aviation maintenance are:

Customization: 3D printing makes it possible to produce components that are made specifically for certain aircraft models and specifications, which eliminates the need for holding enormous stocks of conventional replacement parts.

Speed: Compared to the weeks or months it takes to make traditional parts, 3D printing can generate parts in a couple of hours. As a result, airlines will be able to operate more effectively by decreasing aircraft downtime.

Cost savings: 3D printing can assist airlines in decreasing the requirement for huge stocks of replacement parts and the time necessary to make parts.

The aviation business is changing with augmented reality (AR) technology, particularly in the area of aircraft maintenance. For maintenance personnel, augmented reality (AR) offers a distinctive and participatory experience by fusing real-world scenery with computer-generated imagery. It has the ability to completely change how airplane maintenance is carried out and offers substantial advantages over conventional maintenance methods. Improved accuracy and efficiency are two of the key advantages of AR in aviation maintenance. With AR, technicians may view digital data overlaid on actual things, doing away with the need to consult manuals or schematics on paper. Because personnel can rapidly obtain and understand the information they need, this lowers the likelihood of errors and expedites the maintenance process. Additionally, AR improves safety when doing maintenance. AR lessens the need for professionals to handle heavy equipment, enter small locations, or carry out other potentially hazardous activities by presenting digital information in real-time. Additionally, AR may deliver in-the-moment alerts and cautions to assist technicians in avoiding potential dangers and making wise decisions. The capability of AR to offer training and assistance to both new and seasoned professionals is another benefit in airplane maintenance. With AR, technicians may access information and instructions as they are working, assisting in ensuring that jobs are completed accurately and effectively. A safe and regulated learning environment is provided by AR when it comes to training new technicians. Finally, by increasing the precision and effectiveness of maintenance operations, augmented reality can assist airlines in lowering maintenance expenses. This can also assist airlines in lowering operating expenses and boosting profitability by minimizing the amount of maintenance-related mistakes and downtime. Additionally, AR can offer useful information and insights on the maintenance of aircraft, enabling airlines to choose the best tactics and methods for maintenance.

In summary, augmented reality is a game-changer for the aviation sector, offering major advantages to airlines and aircraft maintenance specialists. AR has the ability to completely change how aviation maintenance is carried out by enhancing accuracy, efficiency, safety, training, and cost-effectiveness. It's conceivable that AR will become more significant in the aviation sector, and specifically in aircraft maintenance, as technology advances.

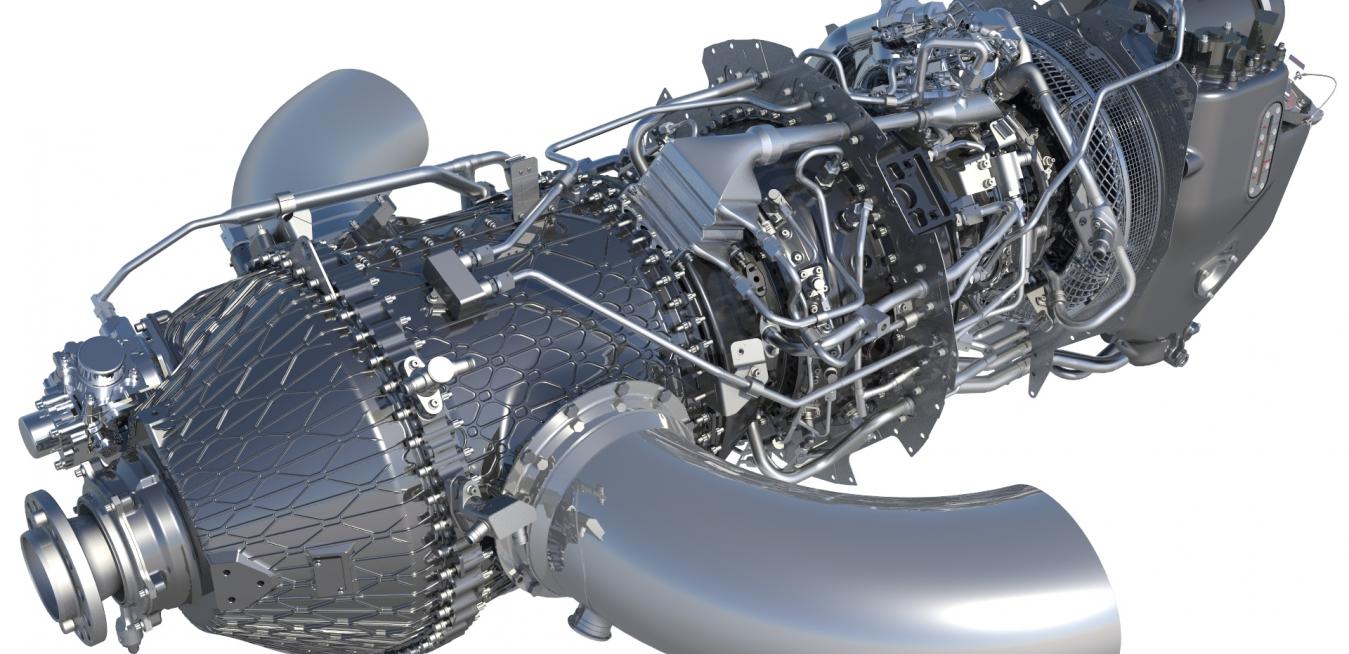

The safe and effective operation of an aircraft depends on the aircraft engine mounts. They serve as a link between the engine and the airframe and assist dampen vibrations and shocks during flight. Enhanced engine mounts have become a viable option to reduce some of the issues that traditional mounts in aviation maintenance encounter as a result of technological and material improvements. Metal and rubber were the traditional materials for engine mounts, which were bulky and often maintained. The rubber aggravated and the metal wore out with time, necessitating periodic replacement. As a result, the aircraft had longer downtime and higher maintenance expenditures. Modern composite materials like carbon fiber and high-temperature resins are being used in the production of new engine mounts in order to address these issues. These materials are more resilient and lightweight than conventional materials, which lowers the aircraft's total weight and improves fuel economy. Additionally, composite materials last longer and require less maintenance since they are more resistant to heat and environmental deterioration. The capacity of improved engine mounts to absorb stress and vibration more efficiently than conventional mounts is one of its main advantages. As a result, there is an improvement in engine performance, a decrease in noise, and less wear and tear on the engine and other parts of the aircraft. In addition, improved engine mounts are made to be quickly and readily interchangeable, which cuts down on the time and effort needed for maintenance and repair. The increased resilience of upgraded engine mounts to corrosion and wear is another benefit. As a result, the mounts are more dependable and durable, requiring less regular maintenance and replacement. These mounts are also made to fit the newest airframes and engines, guaranteeing compatibility and enabling simple installation in new aircraft.

In conclusion, improved engine mounts mark a significant advance in aircraft maintenance science. They provide a number of advantages over conventional mounts, including as reduced weight, increased dependability, and better shock and vibration absorption. Enhanced engine mounts provide airlines and operators with a practical way to increase the performance and lifetime of their aircraft at a reasonable cost due to their increased durability and resilience to environmental deterioration.

A key element of aviation that guarantees the dependability and safety of aircraft is maintenance. Airlines must maintain their fleet of aircraft in high condition and operational readiness while reducing costs and maximizing efficiency in order to meet the growing demand for air travel. Predictive maintenance has been a game-changer in airplane maintenance technology as a solution to these problems. Advanced analytics and machine learning algorithms are used in predictive maintenance, a data-driven approach to maintenance, to foretell when repair is necessary. With the use of this technology, data is gathered from many sources, including as sensors, telemetry, and historical records, and it is then analyzed to find patterns and trends that show when an aircraft component is most likely to malfunction. Predictive maintenance makes it possible for airlines to plan maintenance tasks before a component actually breaks down, preventing unplanned downtime and assuring the dependability and availability of aircraft. Airlines can streamline maintenance procedures thanks to predictive maintenance, which is one of its primary advantages. Airlines may base maintenance efforts on real data and circumstances rather than predetermined timetables or reactive maintenance, resulting in a more effective and efficient use of resources. Predictive maintenance assists airlines in lowering the possibility of unscheduled downtime, which can lead to expensive repairs, lost income, and schedule disruptions. Predictive maintenance also has the benefit of extending the life of airplane parts, which is beneficial for airlines. Airlines can take proactive steps to extend the life of components, cutting the need for replacements and maintenance expenses, by spotting possible issues before they become serious. Additionally, predictive maintenance gives airlines useful information that they may use to plan their fleet management, purchase components, and schedule maintenance. In conclusion, predictive maintenance is transforming the field of aviation maintenance, giving airlines a data-driven method of maintenance that maximizes effectiveness, lowers expenses, and raises safety and dependability. Predictive maintenance is anticipated to become an increasingly significant tool for airlines as the aviation sector develops, assisting them in overcoming the issues of the future. Predictive maintenance is anticipated to become a more crucial tool for airlines as the aviation sector develops, enabling them to manage present-day issues and stay competitive.

With millions of aircraft taking off and landing every day, the aviation sector is one of the fastest expanding businesses in the world. The requirement for efficient and effective maintenance procedures to maintain aircraft in peak condition grows along with the demand for air travel. Here robotics technology enters the picture as a game-changer for the aviation repair sector. Although robotics technology has been available for a while, the aviation sector has only recently seen a significant use of it. Robots and automation systems are utilized to complete a variety of maintenance activities, from straightforward inspections to intricate repairs, lowering the need for human involvement and the possibility of human mistake. Efficiency improvement is one of the primary advantages of robotic technology in airplane maintenance. Maintenance activities can be completed more quickly and precisely by robots than by humans. They also operate nonstop and without breaks, which enables maintenance to be done continuously without affecting production. Additionally, robots can do jobs in risky conditions without endangering human personnel, such as at high altitudes or in the presence of dangerous chemicals. Enhanced safety is a benefit of deploying robotics in aviation maintenance. Robots may be trained to do jobs with the highest level of accuracy, lowering the possibility of human mistake and guaranteeing that maintenance is performed to the highest standards. This is especially crucial for difficult activities like structural inspections, where even a small error might have detrimental effects.

Additionally, the maintenance procedure may be more flexible thanks to robotics technology. Robots may be programmed to carry out a variety of jobs, from straightforward inspections to intricate repairs, enabling maintenance procedures to be customized to the unique requirements of each aircraft. This implies that the maintenance process may be maintained running smoothly while keeping aircraft in peak shape.

Finally, robots technology is completely changing how aviation maintenance is done. Robotics technology is revolutionizing the aviation sector and assisting in ensuring that aircraft are always kept in top condition by minimizing the need for human involvement, boosting efficiency, enhancing safety, and enabling greater flexibility. Future aviation maintenance appears to be becoming more automated and effective as robotics technology continues to improve.

Since its introduction, blockchain technology has transformed several sectors, and the aviation sector is no exception. The requirement for an effective, secure, and trustworthy system to manage supply chains, track components, and maintain track of aircraft maintenance data has long existed in the aircraft maintenance sector. A novel solution offered by blockchain has the ability to speed up these procedures and build a more open and effective system. A secure, impenetrable, and decentralized ledger of data is one of the key advantages of employing blockchain in airplane maintenance. Records are retained in different databases as part of the conventional maintenance procedure, which makes them vulnerable to mistakes, data breaches, and illegal access. With blockchain, data is stored on a shared ledger that is continuously updated and validated by a number of network members. This guarantees the accuracy, transparency, and security of the data recorded.

The capacity of blockchain to improve supply chain management is another significant advantage for airplane maintenance. Currently, the supply chain process is sometimes difficult and time-consuming due to the involvement of several stakeholders, such as producers, suppliers, service providers, and regulatory bodies. Blockchain eliminates the need for human data entry and lowers the possibility of mistakes or fraudulent actions by enabling real-time access to the same information by all stakeholders. With blockchain, data is stored on a shared ledger that is continuously updated and validated by a number of network members. This guarantees the accuracy, transparency, and security of the data recorded. The capacity of blockchain to improve supply chain management is another significant advantage for airplane maintenance. Currently, the supply chain process is sometimes difficult and time-consuming due to the involvement of several stakeholders, such as producers, suppliers, service providers, and regulatory bodies.

In conclusion, the field of airplane maintenance might benefit significantly from the use of blockchain technology. It may assist in streamlining the supply chain process, improving component tracking, and lowering the cost and time related to maintenance thanks to its secure, tamper-proof, and decentralized ledger. Blockchain technology will be essential in fostering innovation as the aviation sector develops and in making sure it stays safe, effective, and affordable.

We can confidently state that the aviation maintenance sector has been significantly influenced by technological improvements. In addition to enhancing the entire maintenance experience for technicians and operators, the use of these cutting-edge technology has also decreased costs and enhanced profitability for airlines and maintenance companies. It is thrilling to think of the potential technologies that will emerge in the future to further change the airplane maintenance sector as technology continues to advance and evolve.

Be First to Comment